Capabilities

Offering the latest casting technology, cost efficient finishing, and high level automation to deliver a quality product, on time and at the right price.

![]()

There is no substitute for experience and with over 247 years of combined experience in our engineering team alone, AETC leads the way in our capability to manufacture a broad range of components.

We pride ourselves in our investment in graduate engineers to bring new ideas and push the boundaries of our capabilities, implementing and developing new technologies to continue our strive for the highest standards of engineering excellence.

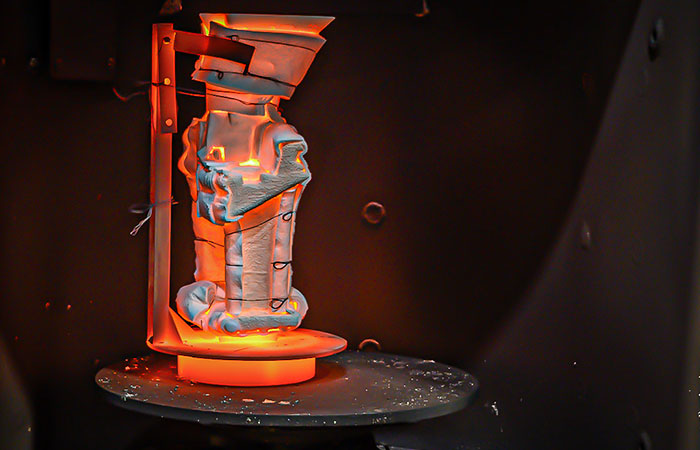

Wax Cluster Injection & Assembly

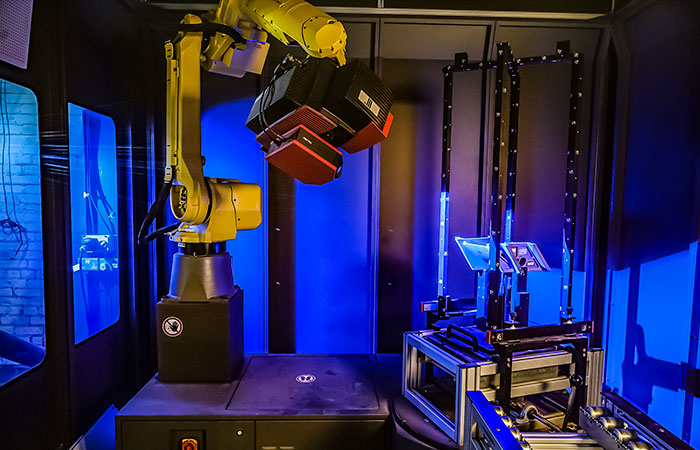

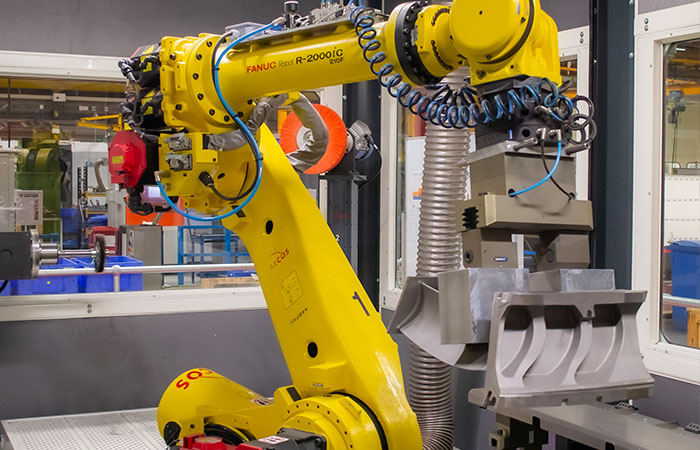

Robot Dipping & Mould Preparation

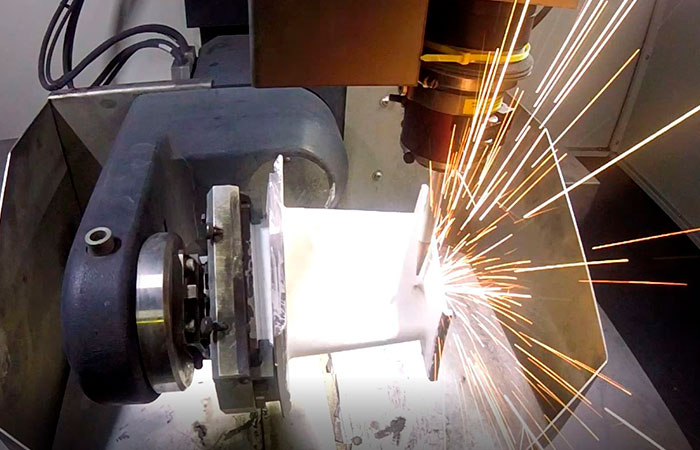

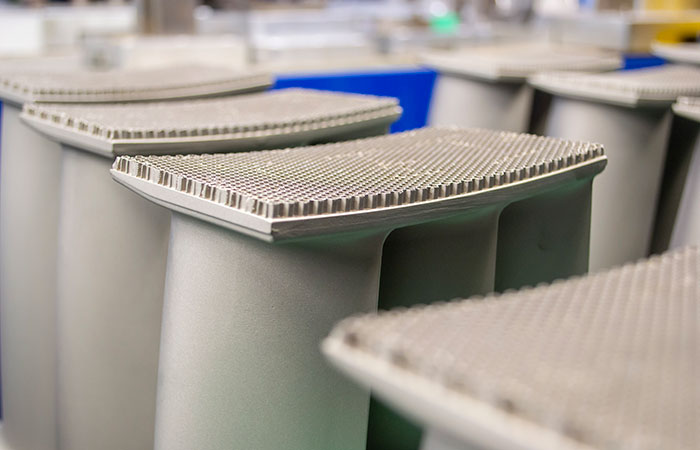

Casting & Machining

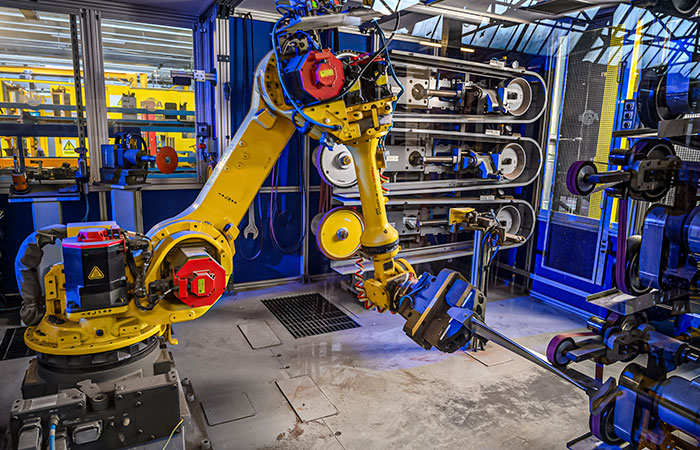

Finishing & NDT

Special Processes

Full Range of Approved, In-House, Special Processes:

Engine Ready Supply

Supply chain management including: